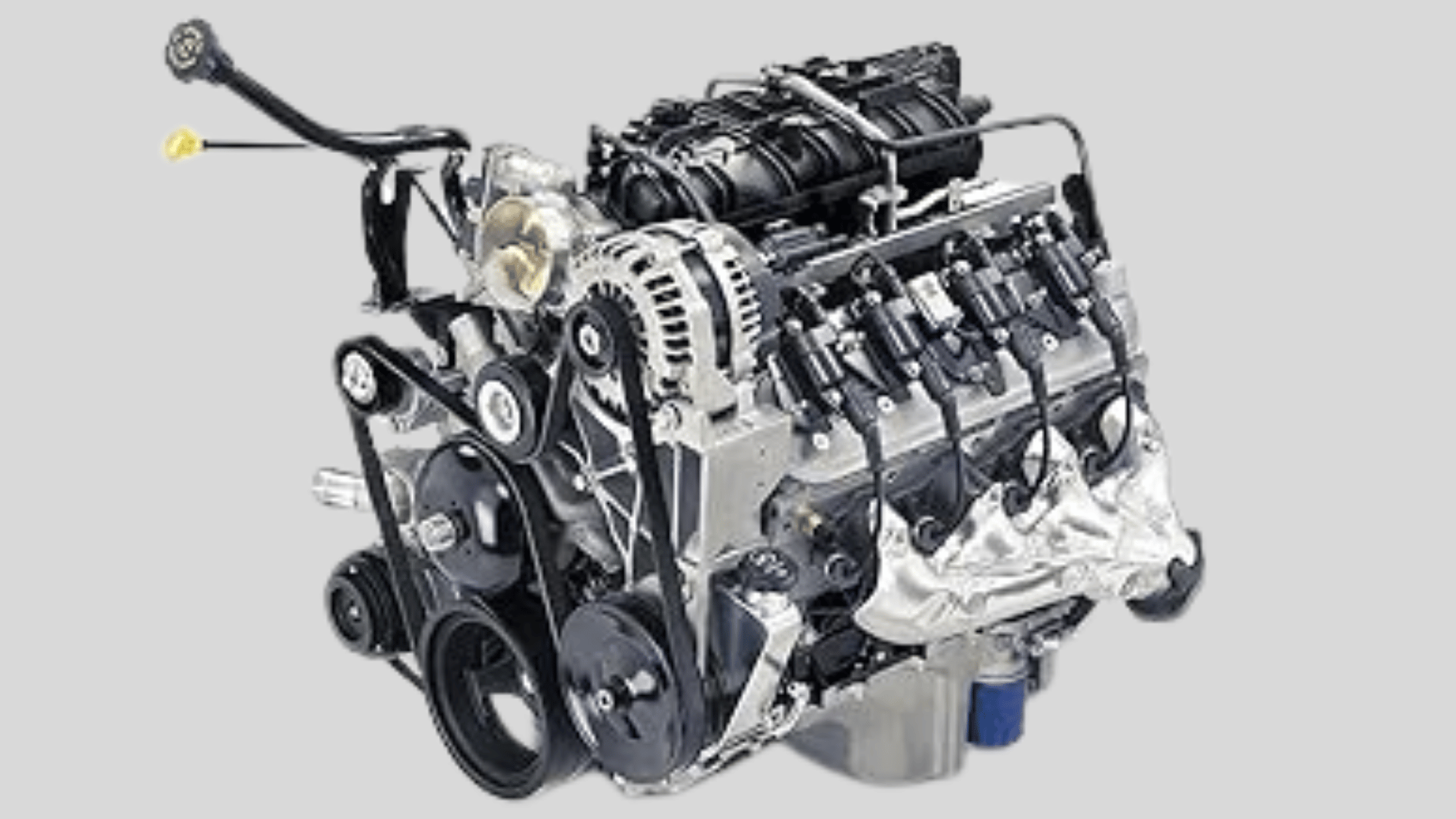

Engines have many moving parts, and each one plays a crucial role.

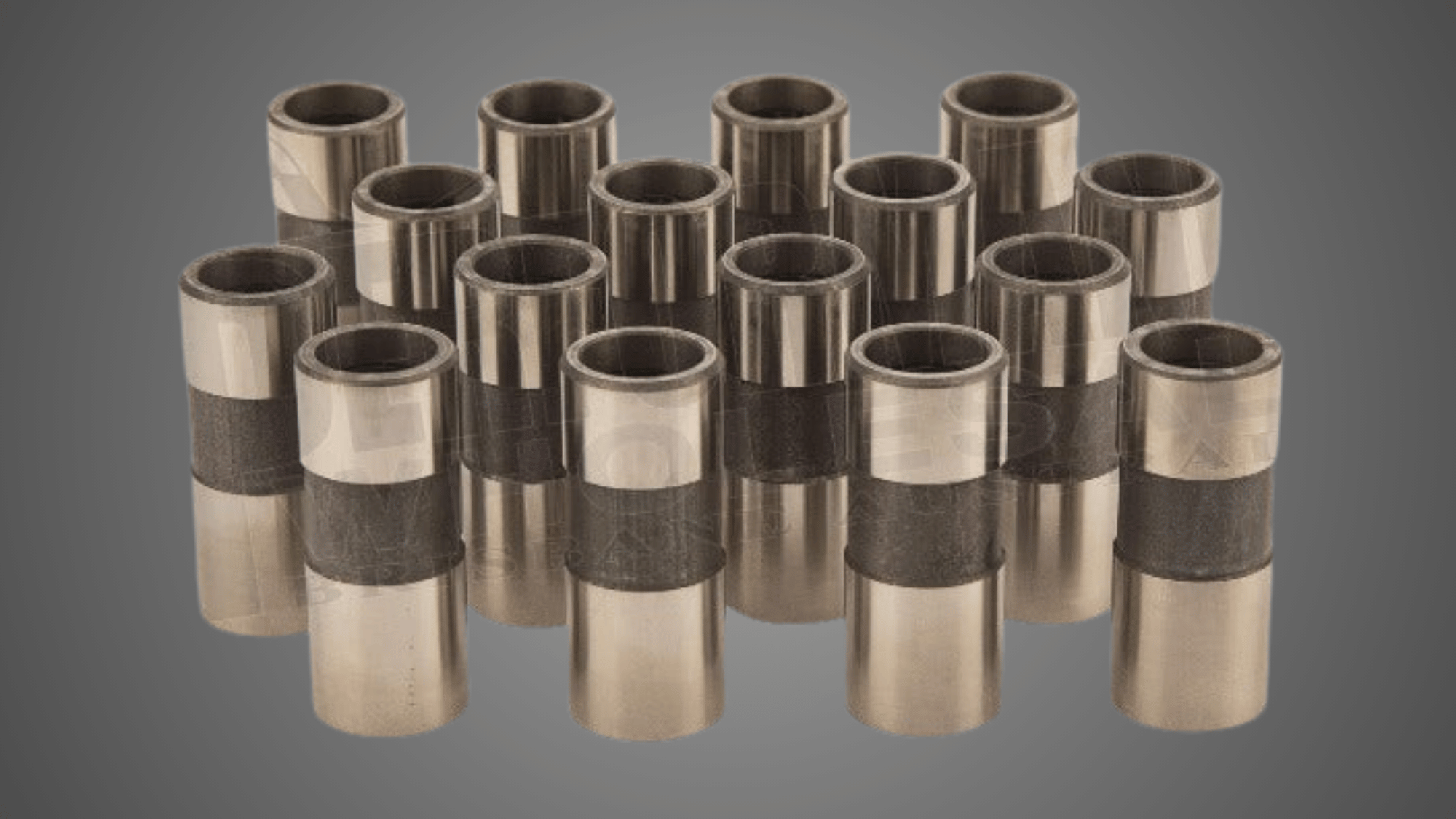

Certain parts are large and easily visible, but lifters are small components that still play a significant role.

They may not stand out at first glance, yet they help the engine run smoothly. Without lifters, the process that keeps a car moving would not work as smoothly.

Many drivers have heard of lifters but are not sure what they do or how they fit into the bigger picture.

This is a common question, and the answer is simpler than it may seem.

By learning about lifters, anyone can gain a deeper understanding of how an engine works. This guide explains their role in clear, simple steps.

What are Lifters in the Engines?

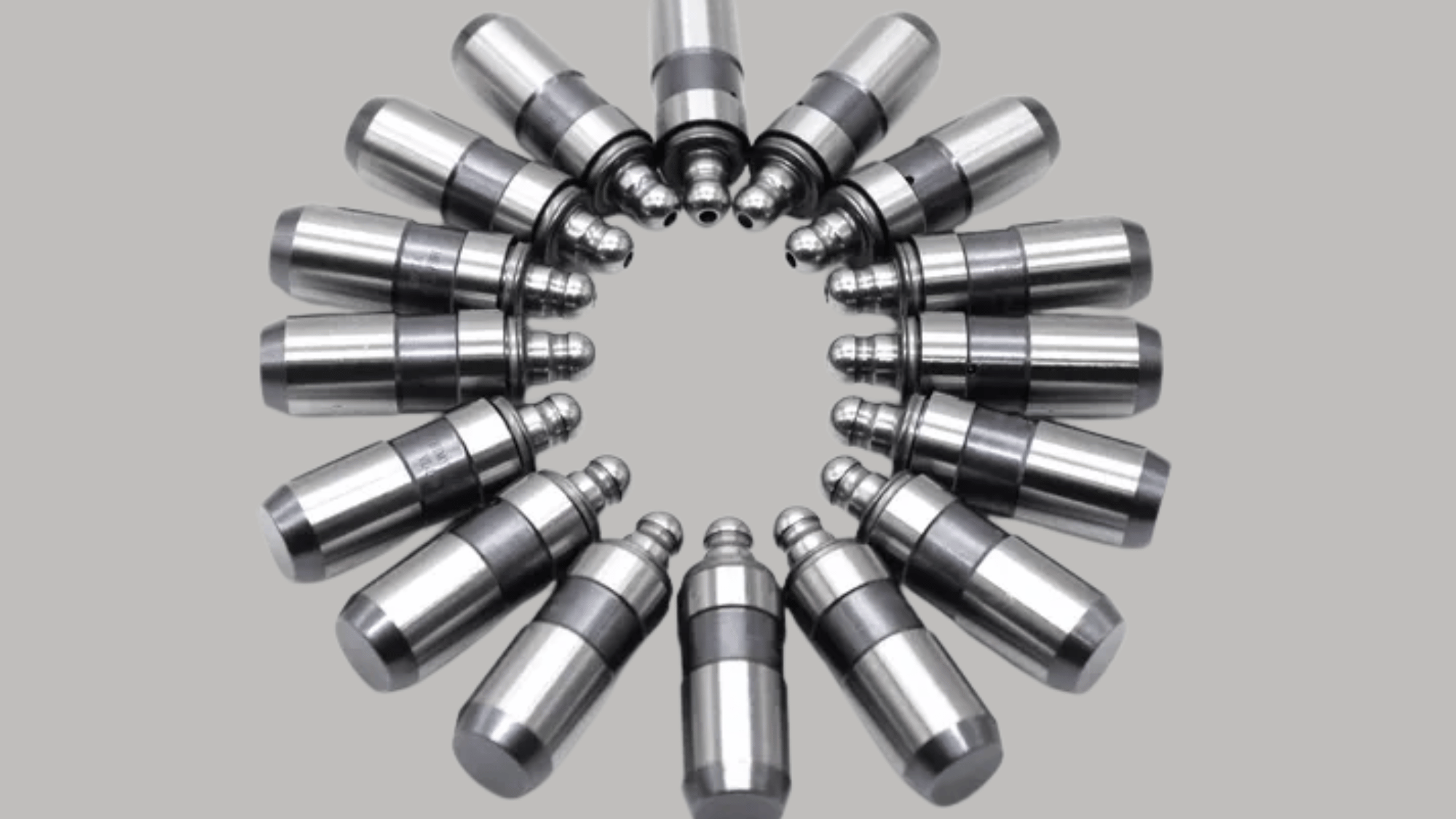

Lifters are also known as valve lifters or tappets. They are small but significant parts inside an engine.

They also help control how and when the engine valves open and close.

Lifters are placed between the camshaft and the valves (or pushrods). This helps air and fuel enter the engine at the right time and allows waste gases to escape after combustion.

Lifters help the engine run smoothly, quietly, and efficiently. If they become damaged, they can cause unusual noises, reduce power, and lead to other problems.

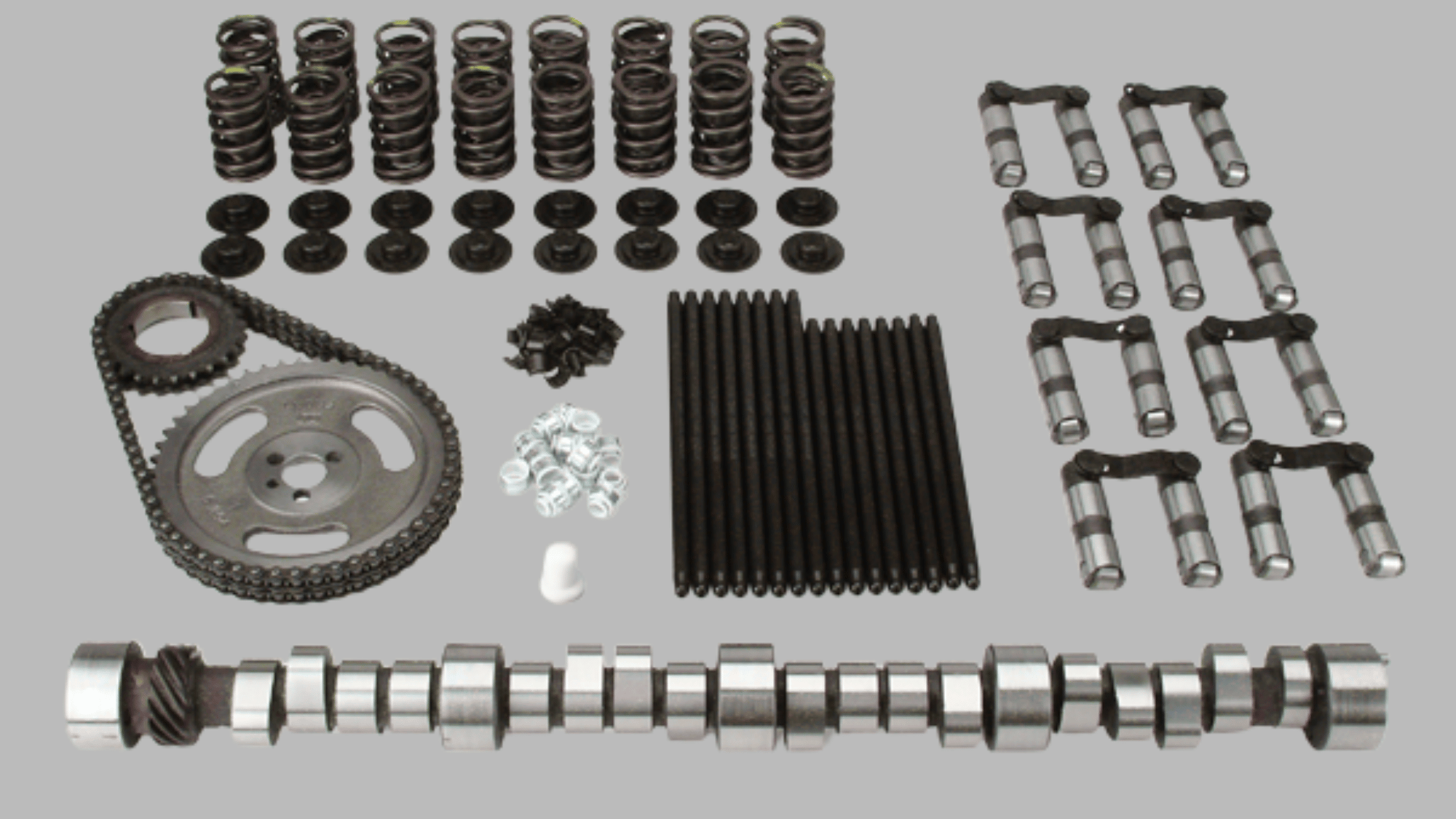

Types of Lifters in Engines

There are 4 types of lifters: mechanical, hydraulic, roller lifters, and solid-roller lifters. Every lifter has its own characteristics and pros and cons.

1. Mechanical (Solid) Lifters

Mechanical lifters or solid lifters are simple in design, consisting of a solid piece of metal that moves the camshaft to open the valve.

These lifters provide accurate valve timing, which is helpful for high-maintenance engines.

They can handle higher engine speed and faster cam profiles. If they are not adjusted properly, they can be louder.

2. Hydraulic Lifters

Hydraulic lifters are filled with engine oil to automatically adjust to manage zero valve clearance.

These lifters reduce engine noise and require less maintenance.

Hydraulic lifters are commonly found in modern vehicles due to their effortless operation.

3. Roller Lifters

Roller lifters have a small roller on the bottom that rolls along with camshaft lobes.

This helps reduce friction and wear, making them last longer.

Roller lifters can be either mechanical or hydraulic lifters and are typically used in high-performance engines to enhance efficiency and durability.

This lifter helps increase high power and protects the camshaft from damage.

4. Solid-Roller Lifters

These lifters are a combination of roller and mechanical lifters, featuring a roller wheel with a solid design.

They provide specific valve control, which reduces friction, and are usually used in racing engines.

These lifters require regular maintenance and valve adjustments due to their solid construction.

How Do Lifters Work in an Engine?

Lifters circulate motion from the camshaft to the engine’s valves, which help them open and shut. This ensures smooth engine performance, proper air-fuel flow, and efficient combustion.

- Lifters play an important role in the engine. When the engine is running, the camshafts begin to rotate.

- The camshafts have parts called lobes, which press against the bottom.

- As the camshafts spin and rise, they push the lifters up. This motion is transmitted to the pushrods and then directly to the rocker arms.

- Then the rocker arms are pushed down on the engine valves, allowing them to open so that air and fuel can enter and exit, as well as toxic gases.

- When the camshaft rotates and passes the lifter, it moves back, allowing the valve to close.

Which Type of Lifter is Best for Your Engine?

Different lifters suit different needs. Hydraulic lifters are quiet and low-maintenance for daily use, while mechanical and roller lifters offer better performance and durability in racing applications, providing greater control and reliability.

| Lifter Type | Best For | Key Features |

|---|---|---|

| Hydraulic Lifters | Normal cars, trucks, SUVs | Quiet, low-maintenance, reliable for everyday driving |

| Mechanical Lifters | Racing, performance builds | Accurate valve timing needs regular adjustment |

| Solid-Roller Lifters | Formula 1, high-performance racing | High RPM use, dynamic cam profiles, and high precision |

| Roller Lifters | Modern engines, high-production builds | Balanced performance, reduces friction, and is durable |

Tips to Protect your Engine lifters from Damage

Protecting your engine lifters can help your engine run more smoothly and last longer.

These simple steps, such as using high-quality oil, warming the engine, and addressing early noises, can prevent lifter wear, noise, or costly damage.

Below are some tips that will prevent the lifters from damage.

- Use high-quality oil to keep lifters smooth and reduce wear. Bonus: Synthetic oil = extra protection.

- Dirty oil can clog lifters. Change oil and filter every 5,000–7,500 km for a healthy engine.

- Revving a cold engine = big stress on lifters. Warm it up for a minute before driving.

- Some oil additives can quiet noisy lifters and clean old buildup, especially in older engines.

- Clicking or tapping? Don’t ignore it. Early noise often means lifter trouble. Get it checked fast!

Conclusion

The lifters in the engine help open and close the engine’s valves at the right time. Without them, the engine wouldn’t work and could become damaged over time.

Lifters may be smaller in parts, but they play a significant role. They connect parts to control the air and fuel that move in and out of the engine.

Taking care of your lifters means changing your oil on time, letting the engine warm up, and being aware of any unusual noises.

By understanding how lifters work and their importance, you can maintain your engine’s health and strength for years to come.