Have you ever wondered how your automatic car shifts gears so smoothly without jerking?

The secret lies in a component called the torque converter. This clever device acts as the bridge between your engine and transmission, making driving effortless and comfortable.

Understanding how a torque converter works can save you from costly repairs and help you make better decisions about your vehicle.

It’s not as complicated as it sounds, and knowing the basics can be incredibly useful.

This blog will break down everything about torque converters in simple terms. You’ll learn what they are, how they function, and why they’re essential for your automatic transmission.

What is a Torque Converter?

A torque converter is a fluid coupling device that sits between the engine and the automatic transmission in most vehicles.

Think of it as the automatic transmission’s version of a clutch, but instead of using friction plates, it uses hydraulic fluid to transfer power.

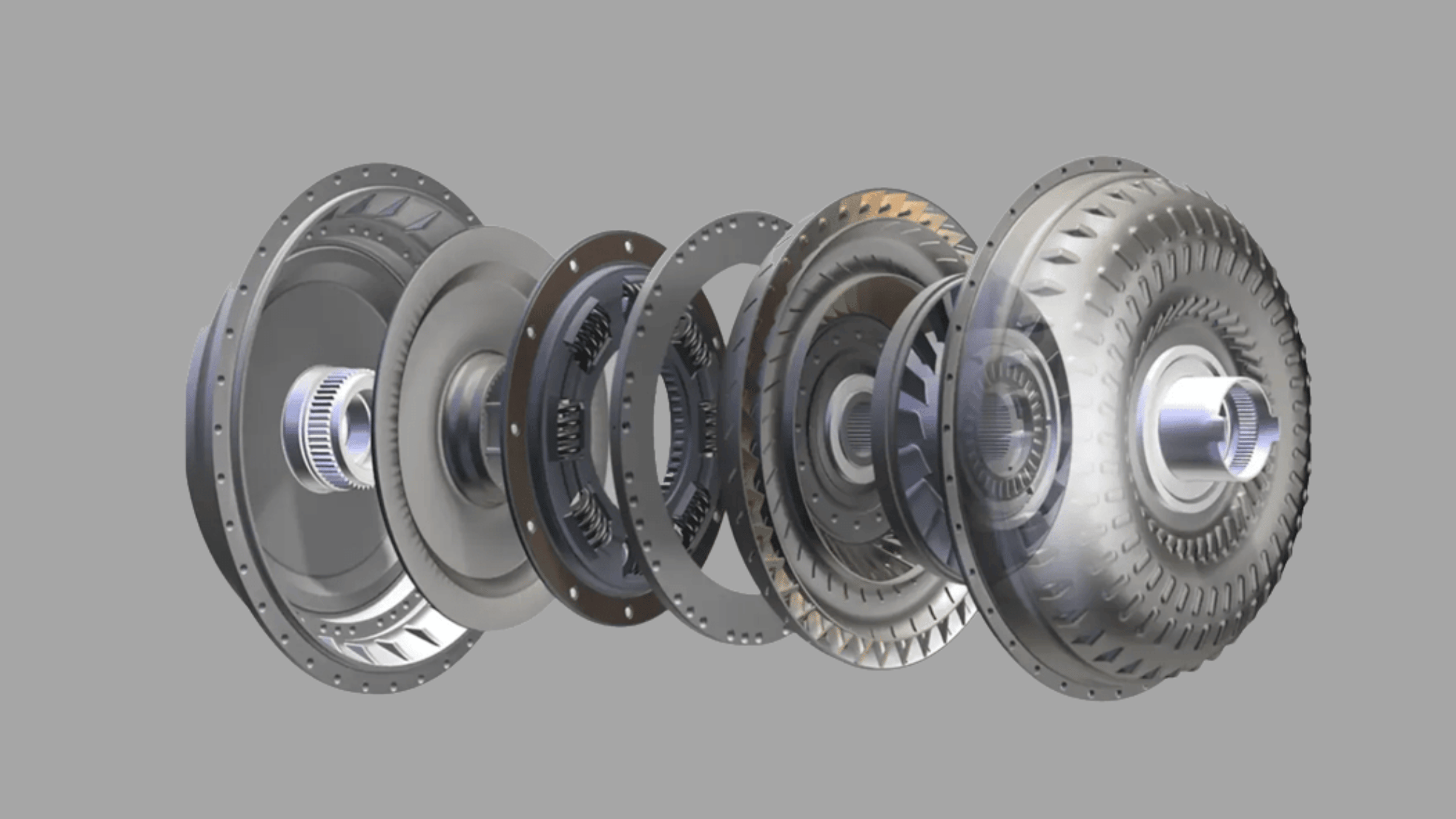

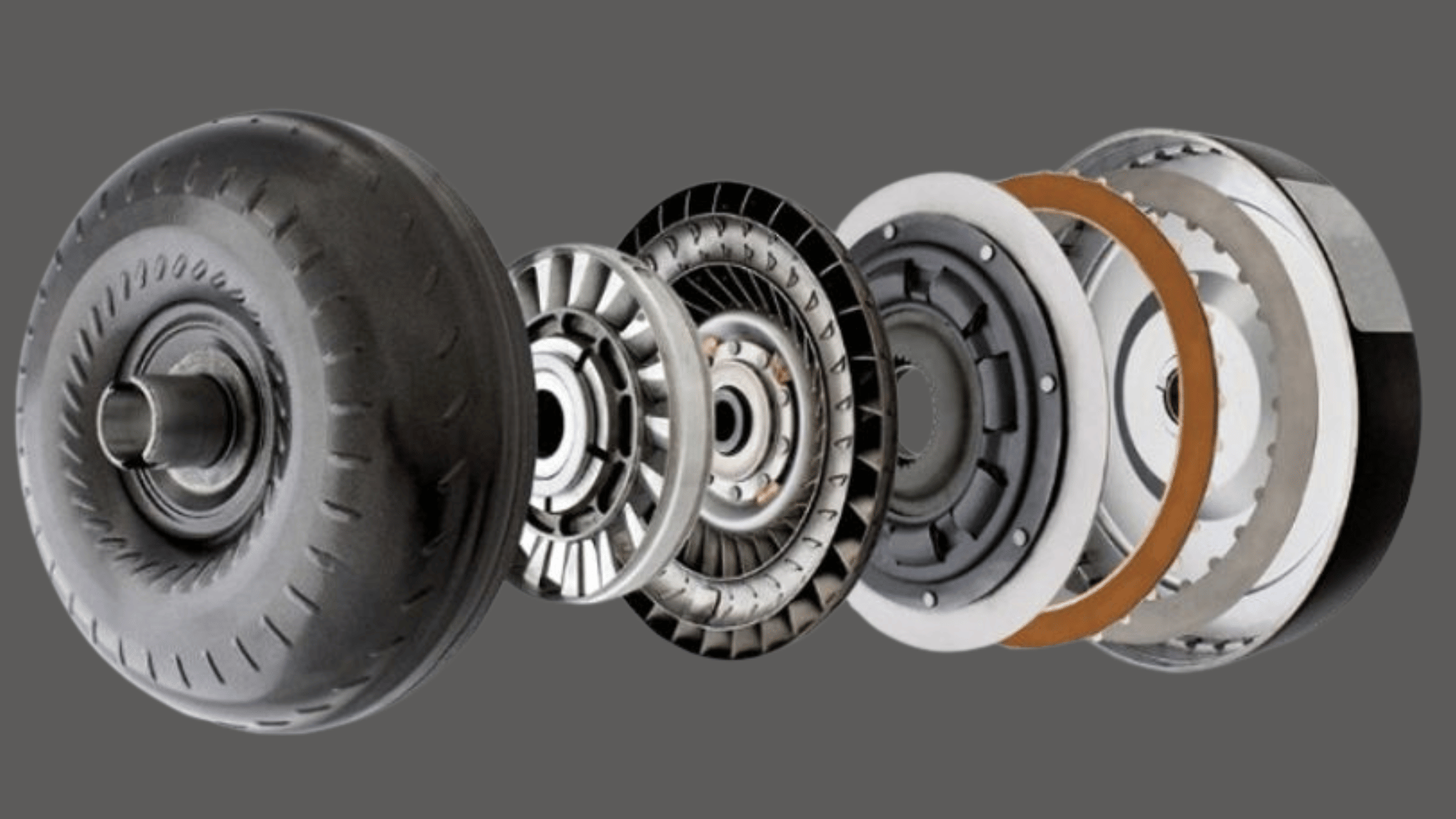

The device consists of three main components: an impeller, a turbine, and a stator. These parts work together inside a sealed housing filled with transmission fluid.

When the engine runs, the impeller spins and pushes fluid against the turbine, which then rotates the transmission input shaft.

Unlike manual clutch systems that create a direct mechanical connection, torque converters provide a smooth, variable connection.

This allows the engine to keep running even when the vehicle stops, and it multiplies torque during acceleration for better performance.

Key Components of a Torque Converter

A torque converter contains four essential parts that work together to transfer and multiply engine power through hydraulic fluid pressure and rotation.

| Component | Primary Function | Key Role |

|---|---|---|

| Impeller (Pump) | Creates fluid flow and pressure | Transfers engine rotation to hydraulic energy |

| Turbine | Receives fluid pressure from the impeller | Converts hydraulic energy back to rotational force |

| Stator | Redirects returning fluid flow | Multiplies torque during acceleration phases |

| Clutch & Fluid | Enables direct connection and power transfer | Provides smooth engagement and heat dissipation |

How a Torque Converter Works: Step-by-Step Process

The torque converter operates through a continuous cycle of fluid movement, creating smooth power transfer from engine to transmission.

Folowing are steps in which a torque converter works:

- Engine starts spinning – The impeller connects directly to the engine’s crankshaft and begins rotating

- Impeller creates fluid motion – Spinning impeller pushes transmission fluid outward using centrifugal force

- Fluid strikes the turbine – High-pressure fluid hits the turbine blades, causing it to rotate

- Turbine drives transmission – The rotating turbine connects to the transmission input shaft, transferring power

- Stator redirects fluid – Returning fluid passes through the stator, which redirects it back to the impeller

- Torque multiplication occurs – During acceleration, the stator multiplies torque by redirecting fluid flow efficiently

- Lock-up clutch engages – At highway speeds, the clutch creates a direct mechanical connection for better fuel economy

- Cycle repeats continuously – This fluid circulation continues as long as the engine runs, providing smooth power delivery

Advantages of Using a Torque Converter

Torque converters offer several practical benefits that make driving automatic vehicles more comfortable and efficient.

The most noticeable advantage is smooth operation – drivers experience seamless acceleration without the jerky motions common in manual transmissions.

This hydraulic system eliminates stalling, allowing the engine to idle while the vehicle remains stationary.

Torque multiplication is another key benefit.

During acceleration, the converter can multiply engine torque by up to three times, providing extra pulling power when needed most.

This feature proves especially useful for towing or climbing hills.

The system also reduces wear on engine components by acting as a buffer between the engine and transmission.

Additionally, modern torque converters include lock-up clutches that improve fuel efficiency at cruising speeds.

These advantages make torque converters ideal for stop-and-go city driving and long highway trips alike.

Common Signs of Torque Converter Problems

Recognizing these torque converter issues early can prevent costly transmission damage and keep your vehicle running smoothly on the road.

- Slipping transmission – Engine revs high but vehicle accelerates slowly, especially during initial acceleration from stops

- Unusual noises – Grinding, whining, or rattling sounds coming from the transmission area, particularly when shifting gears

- Overheating transmission – The temperature gauge shows high readings or a burning smell indicates excessive heat buildup in the system

- Shuddering or vibration – Vehicle shakes or vibrates during acceleration, often felt most noticeably between 30-50 mph

- Delayed engagement – Significant pause between shifting into drive or reverse and actual vehicle movement beginning

- Poor fuel economy – Sudden drop in gas mileage without other obvious causes, indicating inefficient power transfer

To Conclude

A torque converter serves as the unsung hero in your automatic transmission system.

From its clever hydraulic design to torque multiplication capabilities, this component makes daily driving effortless and smooth.

Regular maintenance and early problem detection can extend its lifespan significantly.

When your torque converter functions properly, you’ll enjoy seamless gear changes and reliable performance for years.

Keep an eye out for warning signs like slipping or unusual noises. Your vehicle’s smooth operation depends on this vital component working at its best.